MAIN STYLE TAGS

MOBILE VIEW HTML

YG-1 Supercut Spade Drill

Versatile drilling system from 9.5mm to 114mm diameter up to 25xD

The most versatile drilling system in the world with a wide range of insert sizes per holder

P

M

S

K

N

Browse the Range

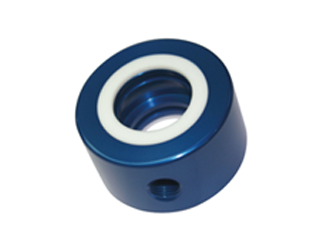

Weldon Shank

Spade Drill Holders

- Through coolant

- Available in 2xD to 25xD max drill depth

- 9.5-65.09mm diameter

Morse Taper Shank

Spade Drill Holders

- Through coolant (via use of coolant ring)

- Available in 3xD to 15xD max drill depth

- 9.5-114mm diameter

Spade Drill

Inserts

- Available in HSS, carbide and powder metal

- Insert grades for steel, stainless steel, HRSA’s, cast iron, auminium & plastics

Advantages

Versatile Diameters

Drill 9.5-114mm diameter using just 9 different holders

Drill Deep Holes <25xD

Holders available in a wide range of lengths up to 25xD

Quick Set Up Times

Inserts can be changed over on the machine for faster set up

Self Centering Inserts

For extremely accurate drilling even in deep holes

Features

Wide Range of Sizes

Inserts available in both metric and imperial diameters

Multi-Material

HSS, Carbide & Powder Metal grades for a wide range of materials

Manual or CNC

Suitable for both CNC and conventional machining

Flat Bottom Inserts

Available for creating a flat bottom in a pre‑existing hole

Spade Drill Inserts

| HSS 5% Cobalt T15/M4 | Powder Metal M48 |

Solid Carbide K20 |

Solid Carbide P40 |

|

|---|---|---|---|---|

| Application | First choice for general machining of all materials. | For increased tool life over T15. Ideal for stainless steel, harder & tougher materials. | Ideal for high alloy steels, stainless steel, HRSA’s & aluminium. | Gives ultimate performance on all steels. |

| Unstable Machining | ✅ | ✅ | ❌ | ❌ |

| Stable Machining | ✅ | ✅ | ✅ | ✅ |

Spade Drill Holders

Drill from 9.5mm up to 114mm using just 9 different sized holders!

Supercut holders are available for short holes to deep holes up to 25xD. As the insert is self-centering, deep hole drilling is possible with reliability and accuracy.

For holders 15xD and above, it is recommended that you pilot drill 1xD with a short length spade drill of the same diameter (do not pilot drill with a smaller diameter drill or drill point with a different angle - this will cause tool failure.) HSS or PM inserts are recommended for drilling above 7xD.

Weldon holders have through coolant supply from the rear of the shank. Morse taper holders have through coolant on the side of the shank above the morse taper. Machines without through coolant can be adapted by using a coolant adapter with a morse taper shank tool.

Grade Guide

| Grade | Chipbreaker | Materials | Features & Benefits |

|---|---|---|---|

| PC2505 | MM | Hardened Steel 45-60HRC |

Ideal for continuous-light interrupted cutting at medium-low surface speeds on heat treated steel & high hardened steel with excellent wear resistance. |

| PC2501 | MM | Hardened Steel / Pre-Hardened Steel 35-50HRC |

Ideal for continuous-light interrupted cutting at medium-low surface speeds on high hardened steel & pre-hardened steel with excellent impact resistance. |

| PC3700 | MF MM |

Steel <40 HRC |

Dedicated steel grade for continuous-light interrupted cutting at medium-high surface speeds. Provides advanced performance & maximum efficiency. |

| PC5300 | MM MF ML |

Steel <40 HRC

Stainless Steel

HRSA's

Cast Iron

|

General PVD coated grade with high toughness for longer tool life. Suitable for light-heavy interrupted cutting at medium-high surface speeds. |

| PC5400 | MM MF ML |

Steel <35 HRC

Stainless Steel

HRSA's

Cast Iron

|

General purpose grade with excellent wear resistance & surface roughness when low speed machining. Ideal for continuous-heavy interrupted cutting. |

| PC6510 | MM | Cast Iron |

Specialised grade for multi-purpose milling applications of cast iron. Suitable for continuous-light interrupted cutting at medium-high surface speeds. |

| PC9530 | MM | Stainless Steel |

Ultra fine substrate for medium & roughing in stainless steel milling. Ideal for high feed continuous-light interrupted cutting. |

| H01 (Uncoated) | MA | Non-Ferrous |

Dedicated non ferrous grade for high speed, high feed milling & mirror surface finish. Uncoated polished grade for maximum swarf control in medium-high speed cutting. |

| UNC840 (CVD) | ML | HRSA's |

Premium grade for machining of HRSA including Inconel, Hastelloy, Titanium alloy etc. Ideal for continuous-light interrupted cutting at high speed-low feed machining. |

Application

Material Suitability

| Material | Excellent | Good |

|---|---|---|

|

P

Steel

|

• | • |

|

H

Hardened Steel

|

• | • |

|

M

Stainless Steel

|

• | • |

|

S

HRSA's

|

• | • |

|

K

Cast Iron

|

• | • |

|

N

Aluminium & Non-Ferrous

|

• | • |

Possible Machining Methods

Face Milling

Trochoidal Milling

Side Cutting

Slotting

Circular Interpolation

Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

Or

Checkout as a Guest

Place your order without creating an account for extra convenience.