MAIN STYLE TAGS

MOBILE VIEW HTML

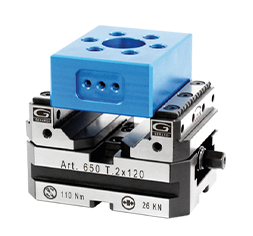

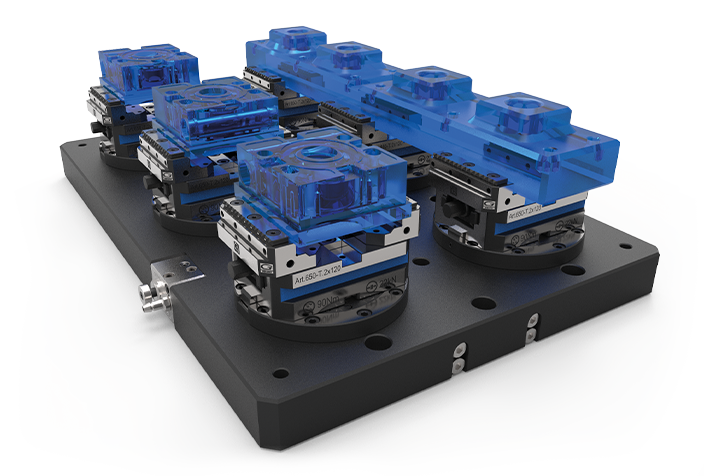

Gerardi Compact Grip

High Precision Self Centering Modular Machine Vice

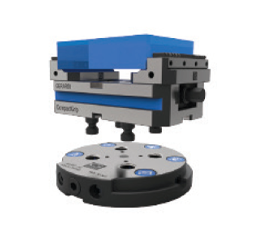

Ideal for 3, 4 and 5 axis vertical or horizontal machining. The widest range of modular jaw plates and accessories including Compact Grip Zero Point Quick Change Tables.

Gerardi Compact Grip Pyramids & Riser Blocks

Special profile with corner protection for roughing stainless steel and titanium

Advantages

Versatile Machining

First choice for slotting and profiling with one tool in stainless steel, titanium and steel machining applications

Double Core

The unique double core design promotes chip evacuation when slotting and improved stability when profiling

Ultra High Performance

Maximum tool life and vibration free machining in roughing and finishing applications

Product Scope

Extremely durable & reliable end mills built to take on the toughest materials available with 4 or 5 flutes

Features

Ultra Heat Resistant

Advanced Y1200 coating offers protection against heat build up improving performance and tool life

High Performance

First choice for high speed machining & high metal removal of stainless steel, titanium and soft steels

Unique Flute Design

Variable flute design featuring multiple helix helps increase performance, reduce vibration and eliminate chatter

Optimised Cutting

Sharper cutting edges combined with optimised edge preparation provides excellent performance in sticky materials

Compact, Rigid & Precise

Modular

Jaw plates for soft, regular & hard materials

Precision

All working surfaces are ground within +0.02mm

No Wear

Made from heat treated HRC60 alloy steel

Compact Grip combines high clamping power, a compact rigid base, 20 micron accuracy and 60 Rockwell case hardening with a wide range of interchangeable jaw/clamping plates. Grip on just 3mm or full jaw height. Superior clamping force, no workpiece stamping or dovetails required, just GRIP & GO.

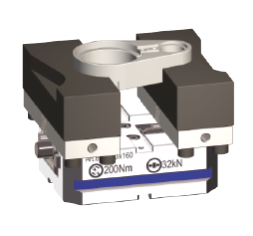

Zero Point Ready

The Gerardi ZERO POINT modular system is the easiest and most cost-effective way to reduce down time and increase profits.

It can be used on machines bed with interface plates, on 5 axis machine or on tombstones.

Compact Grip is compatible with the most popular pallet change systems, but also with Gerardi Zero Point Size 1 and 2.

No need for adapter plates. Supplied with pull stud. Zero Point can be integrated in risers.

In the Box

With each ART.650 Compact Grip Machine Vice

- 1 box wrench: ART.375

- Pair of self centering keys

- Nuts: ART.650G

- Nuts: ART.297

- 2 positioning keys

- 1 workstop: ART.370EM

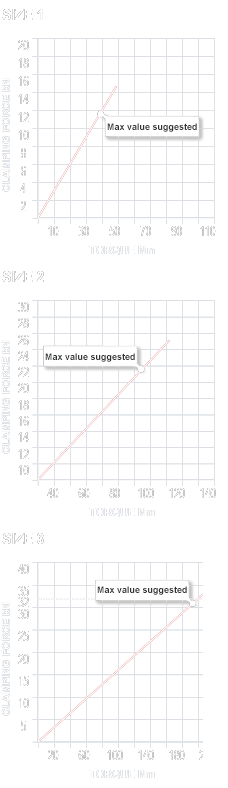

Clamping Forces

MECHANICAL CLAMPING ART. 650/950 - No workpiece crimping or dovetailing required. Double the clamping force of competitor vices.

Specifcations

Hardened & Ground

HRc60 hardened steel base, jaws and lead screw, overall accuracy +0.02mm

Highest & Most Consistent Clamping Forces

12-32kN clamping forces easily achievable due to the lead screw design

Multiple Ways to Locate the Vice

Vice can be positioned with ground keyways (with tenons), quick clamping plates (with 4 pull studs), zero point (1-2 pull studs) or with centering pin (for 5 axis table)

Self Centering Reversible Step Jaws

High clamping accuracy, power and pull down action. Self centering jaws can be adjusted

No Wear

5 years warranty on vices and all components

Single or Double Clamping

With additional fixed jaw (ART650X), 2 workpieces can be clamped with 1 vice

Modular Jaw Plates

With different teeth profiles for specific materials, rough or finish machining

Downloads

Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

Or

Checkout as a Guest

Place your order without creating an account for extra convenience.