Custom solutions available

Excellent value and reliability

Expert technical support

MAIN STYLE TAGS

MOBILE VIEW HTML

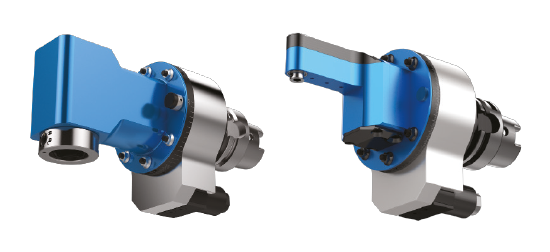

BENZ are known for their innovation, precision & reliability.

Trusted by leading machine tool manufacturers, BENZ are used by major aerospace, automotive, energy and medical manufacturers.

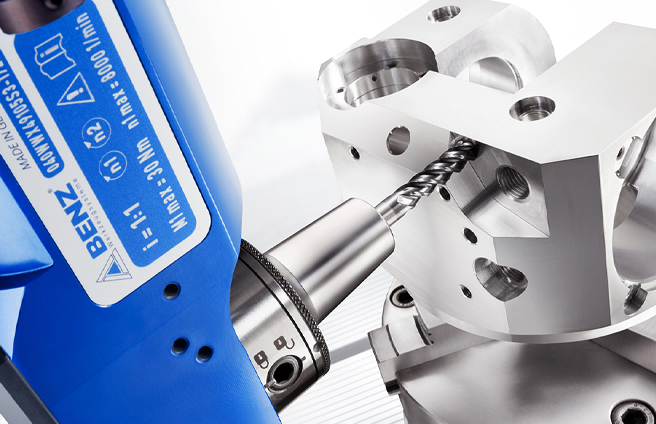

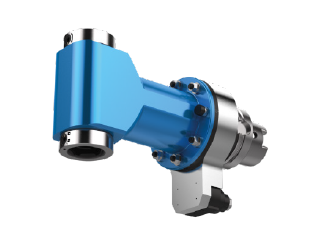

From the extra-small to ultra-large XXL angle heads

Propriety gearing system enables lightweight design; no other angle head can deliver the same torque and rigidity as Benz

Standard, semi-custom or fully customised designs

Plug and play; angle heads are manufactured for the specific machine tool

Wide range of output options such as ER, Weldon, face mill arbor, whistle notched or modular systems Benz Capto, KM & SolidFix

Coolant options: External, high pressure through spindle or through retention pin/stop block

Make an Enquiry

Please send an enquiry below to our expert technical team who are on hand to support any angle head projects or questions you have.

German made.

Innovative, precise and reliable.

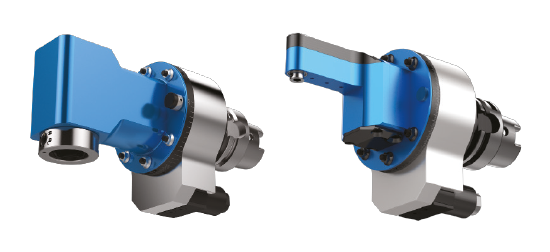

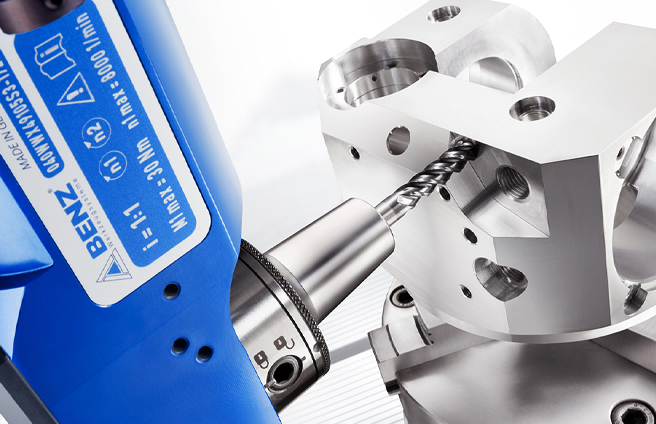

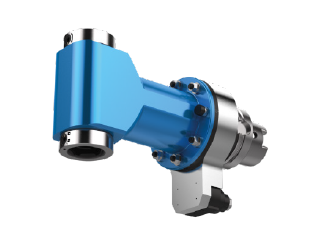

BENZ standard angle heads are based on 7 models, each with different benefits.

Depending on the model, they can be supplied with internal or external coolant, modular or fixed output and a range of lengths/reaches.

Mono WSX

Machining without spatial constrain

Duo WZX

Machining in opposite direction / with different tools

Forte WWX

Machining for spatial constraint / maximum usable tool length

Slim WGX

Machining for spatial constraint / maximum usable tool length

Slim WGX-S

Machining extreme spatial constraint / maximum usable too length

Fix WFX

Special machining at fixed angle

Flex WDX

Machining in any variable position

With BENZ, anything is possible.

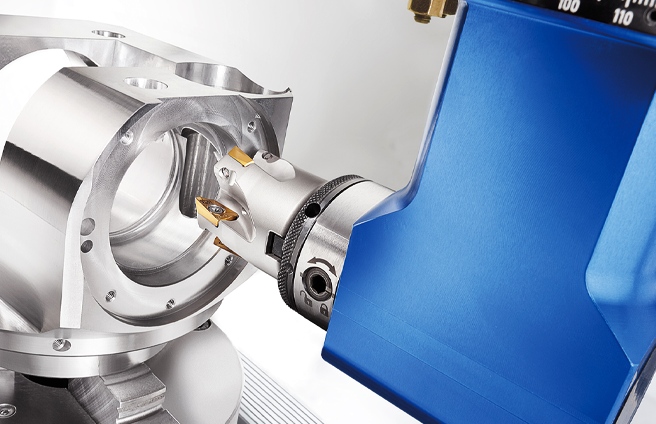

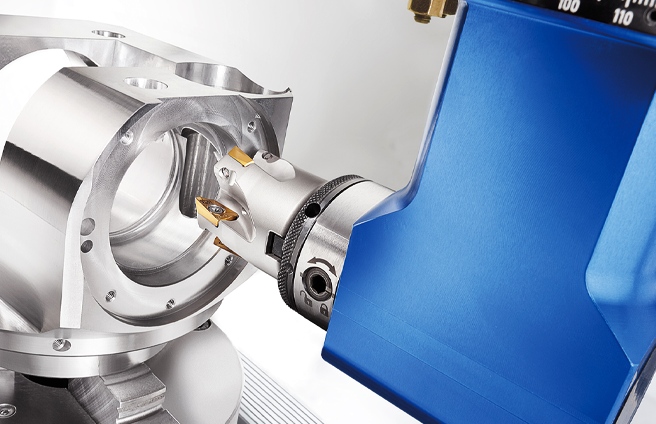

From simple modifications to 100% custom designs, Benz can manufacture angle heads to suit the most difficult requirements.

Benz can develop and produce angle heads to your exact specifications. From small adaptations on existing models to highly complex new developments, Benz offer high quality, affordable solutions. Benz's tried and tested components and systems provide you with limitless possibilities.

We’re a partner from the beginning & beyond.

Project Management

Our goal is to support you in your tasks. Thanks to many years of expertise with BENZ products, our technical team are here to help to make your production easier and more efficient.

Cutwel will work alongside the end-user to find the best solution for the application

Full 3D modelling available

Support in installation if required

With the support of BENZ’s expertise, a solution will be proposed to best suit the machine tool and application

Service & Repair

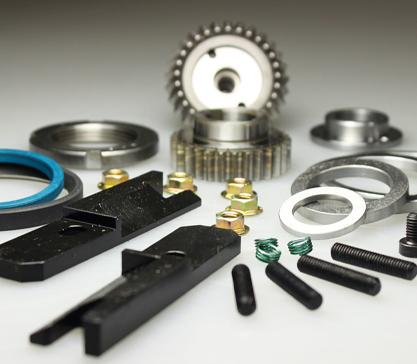

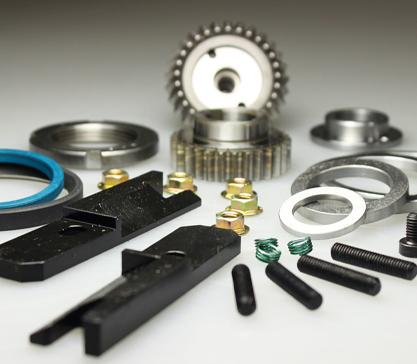

Benz offers full repair, rebuild, and maintenance services for angle heads. Whether damaged or underperforming, most angle heads can be restored to almost new condition.

Regular servicing and preventative maintenance

Quick and professional analysis of damage

Crash repairs from small bumps to full rebuilds

Rapid Repair & Spares

Ensure minimal downtime costs before incidents occur by purchasing a rapid repair kit. It includes all wear and special parts for your unit, providing reliable support even for custom solutions.

Reduce downtime costs due to a machine standstill

All critical wear and special parts available

Rapid repair kits can be purchased for any new or old Benz angle head

System Technologies.

Modular output, additional torque support, industry 4.0 integration, 5 axis heads, C-Axis integration. Benz angle heads have a huge range of options to improve the application of the head.

Benz Capto Modular

Benz SolidFix Modular

3-4 Pin Torque Support

C-Axis Positioning

5 Axis Heads

i-Com Digital Name Plate

Angle head solutions for a range of industries & applications.

Heavy Industries

BENZ produce some of the world’s largest angle heads, ideal for heavy industries such as oil and gas, marine and energy. From standard XXL heads to complete custom designs, the angle head can be produced to suit any machine tool and application. Special adaptations can be provided such as Hirth couplings, exchangeable heads and modular interfaces.

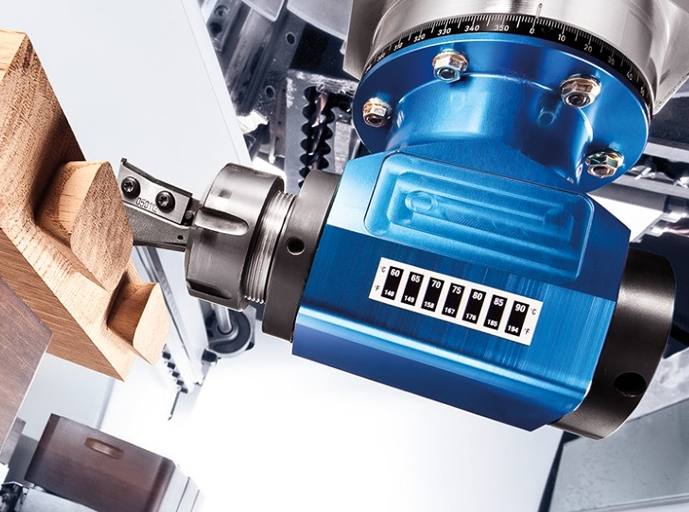

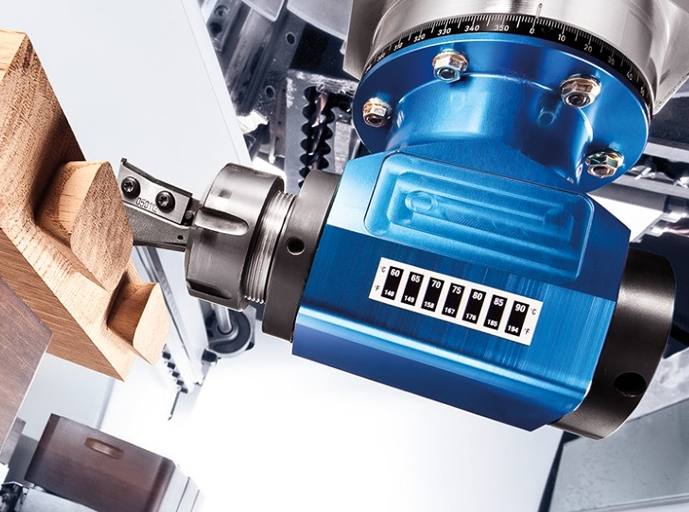

Woodworking Solutions

Economically process wood and composites: We provide angle heads for drilling, milling, sawing and other special applications. BENZ units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation.

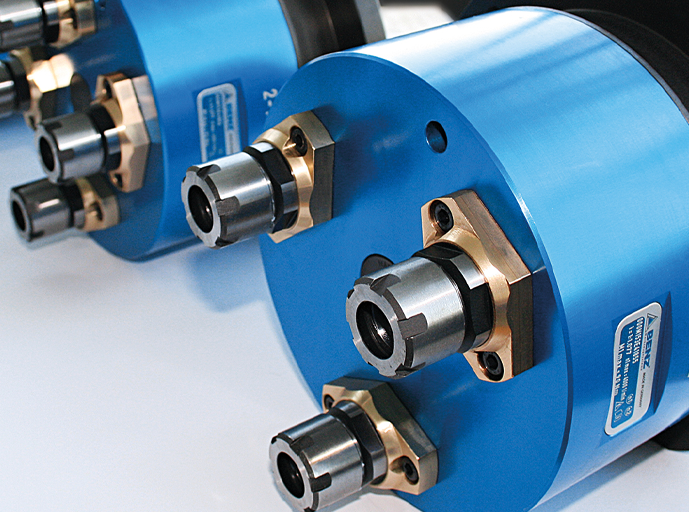

Multi-Spindle Angle Heads

Bring together similar or diverse machining operations to reduce operating times (usually involves multi-spindle heads).

The potential applications are virtually limitless: Drilling, threading, counterboring, reaming, milling, etc.

We work in close co-ordination with you, the customer, to find the perfect solution for your application. Using proven standard components as a basis, we create the optimal multi-spindle solution for you

Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

Or

Checkout as a Guest

Place your order without creating an account for extra convenience.