Solid Shank Turning Tools

The UK’s biggest and best range of solid shank turning tools for all inserts & applications.

|

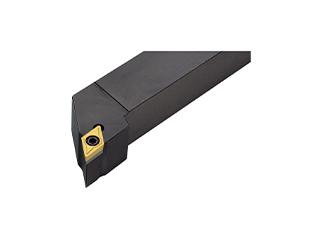

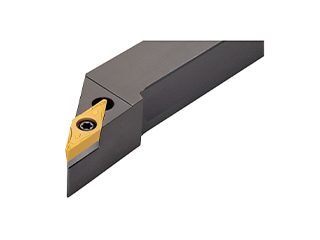

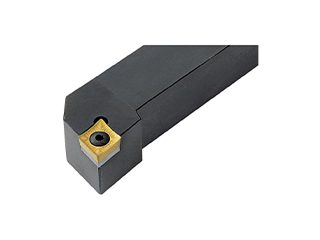

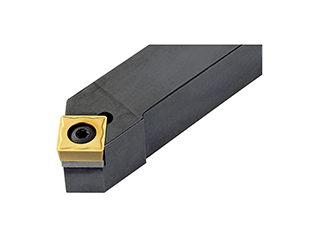

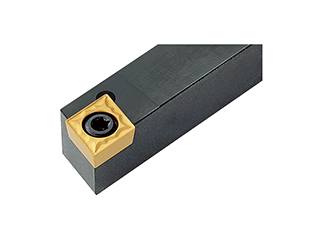

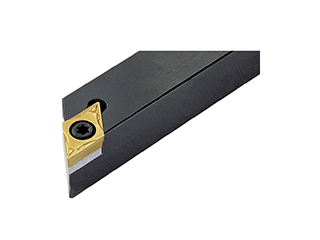

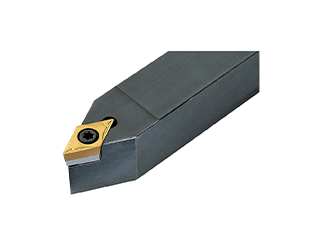

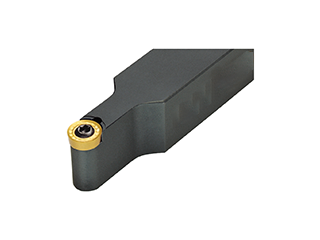

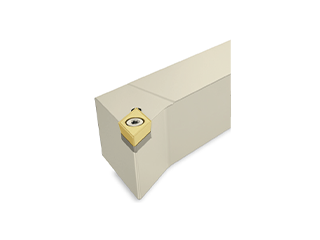

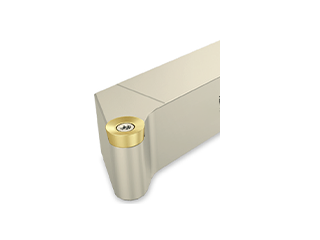

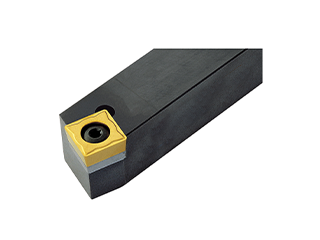

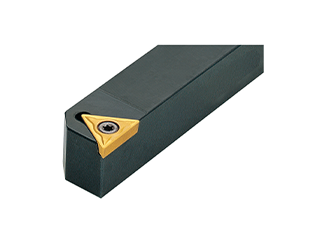

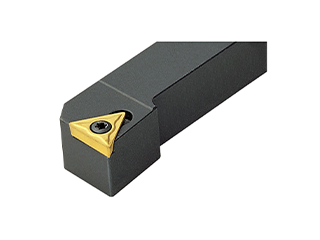

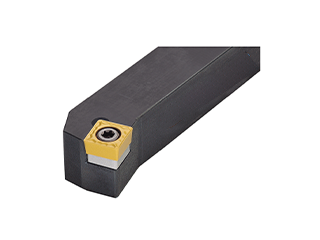

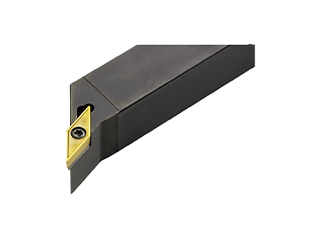

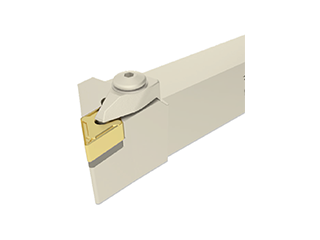

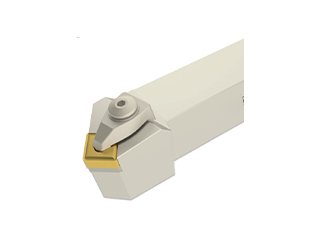

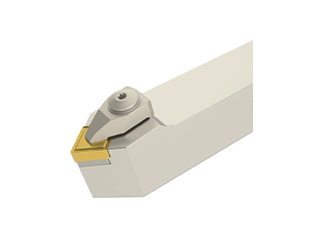

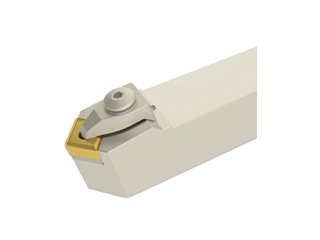

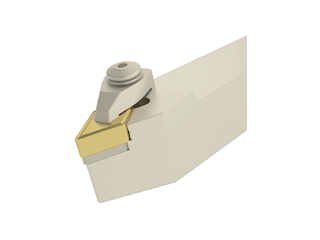

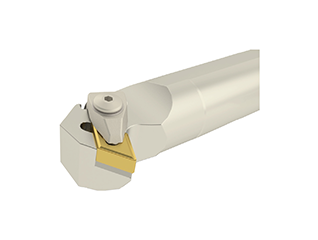

Screw On Clamp Solid Shank Turning Tools

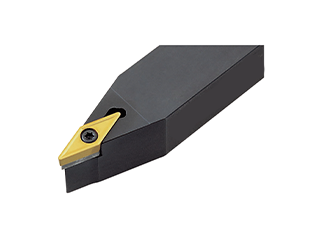

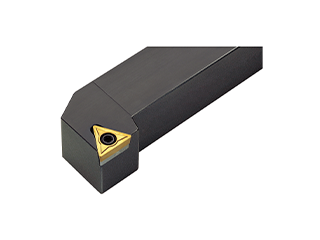

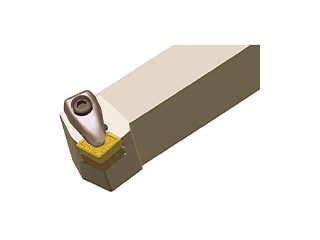

Lever Lock Solid Shank Turning Tools

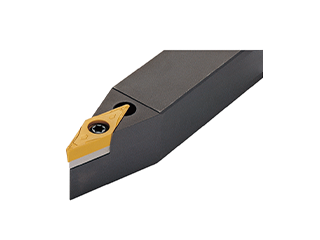

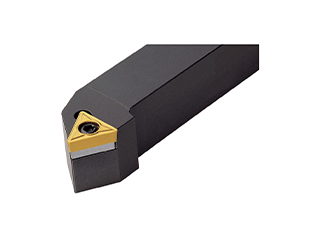

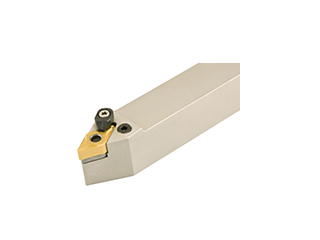

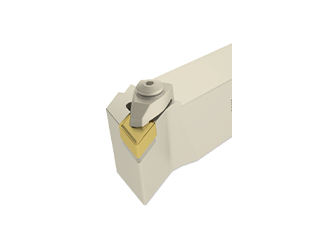

Double Clamp Solid Shank Turning Tools

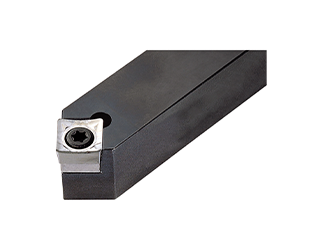

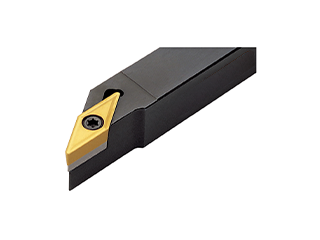

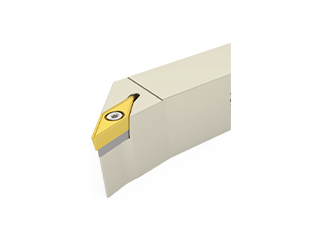

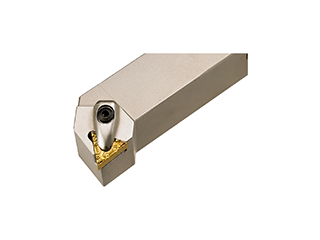

Top Clamp Solid Shank Turning Tools

Multi Lock Solid Shank Turning Tools

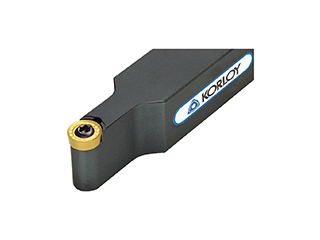

Hole Clamp Solid Shank Turning Tools

What are the benefits of Carbide Shank Boring Bars

Carbide shank boring bars offer several advantages for precision machining operations, including enhanced rigidity, improved vibration resistance, and increased tool life especially in deep hole boring applications. These benefits result from the superior hardness and strength of carbide, which allows for the machining of materials at higher speeds while maintaining dimensional accuracy. Additionally, carbide's resistance to wear and tear means that these boring bars can sustain performance over extended periods, reducing the need for frequent replacements and thus lowering overall machining costs. This makes carbide shank boring bars an efficient and cost-effective choice for a wide range of industrial and manufacturing applications.

How to choose the right carbide shank boring bar for your application

Choosing the right carbide shank boring bar for your application involves considering several key factors:

- Depth of Cut and Reach: The length and diameter of the boring bar should match the depth of cut and the reach required by your application. Longer bars can reach deeper, but may require a larger diameter to prevent deflection.

- Vibration Resistance: For applications where vibration is a concern, opt for carbide shank boring bars designed with anti-vibration features. This may include bars with a damper inside or those made from a specific carbide grade that reduces vibration.

- Tool Holder Compatibility: Ensure the shank size and shape of the boring bar are compatible with your tool holder. This ensures proper mounting and stability during machining. Where needed consider using a split boring bar sleeve.

- Coolant Capability: Some boring bars are designed with internal coolant channels. If your machining process benefits from coolant delivery directly to the cutting edge, select a bar that supports this feature.

- Insert Compatibility: For applications where vibration is a concern, opt for carbide shank boring bars designed with anti-vibration features. This may include bars with a damper inside or those made from a specific carbide grade that reduces vibration.

By carefully evaluating these factors in relation to your specific machining needs, you can select a carbide shank boring bar that optimizes performance, precision, and tool life for your applications.

Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

Or

Checkout as a Guest

Place your order without creating an account for extra convenience.