Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

Or

Checkout as a Guest

Place your order without creating an account for extra convenience.

MAIN STYLE TAGS

MOBILE VIEW HTML

High helix cutting edge provides low cutting resistance and enhanced stability when taking large depths of cut.

| Application |

|

| Diameters | 10-63mm |

Double core geometry for slotting and profiling, long tool life and best all-round performance

| Application |

|

| Diameters | 50-125mm |

Best for profiling offering high feed rates and tool stability

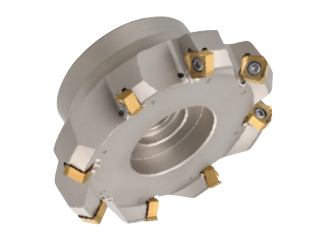

Improved screw design improves insert clamping

Advanced minor cutting edge improves surface roughness

Strong durable double sided insert with 8 cutting edges

Chip breakers and grades to suit a range of materials

Particularly suited to stainless steel machining due to sharp cutting edge

Reduces cutting loads and improves surface finish

Enhances chipping resistance and prevents premature fracture

Improved holder design improves chip evacuation

| Chipbreaker | Cutting Edge | Application | Description |

|---|---|---|---|

| ML |  |

Stainless Steel / HRSA's | Chip breaker with low cutting load is ideal for machining hard‑to‑cut materials such as stainless steel, titanium, inconel and hastelloy |

| MM |  |

General Machining | Optimal for milling in general machining conditions |

| Grade | Chipbreaker | Materials | Features & Benefits | PC3700 | MM | Steels <40 HRC

| Dedicated steel grade for continuous-light interrupted cutting at medium-high surface speeds. Provides advanced performance & maximum efficiency. |

|---|---|---|---|

| PC5300 | MM ML |

Steel <40 HRC

Stainless Steel

HRSA's

Cast Iron

|

General PVD coated grade with high toughness for longer tool life. Suitable for light-heavy interrupted cutting at medium-high surface speeds. |

| PC6510 | MM |

Cast Iron

|

Specialised grade for multi-purpose milling applications of cast iron. Suitable for continuous-light interrupted cutting at medium-high surface speeds. |

| PC9540 | ML | Stainless Steel |

Dedicated grade for hard to cut stainless steel, PVD oxide film prevents wear caused by high temprature machining. Suitable for medium-heavy interrupted cutting at medium-low surface speeds. |

| Material | Excellent | Good |

|---|---|---|

|

P

Steel

|

• | • |

|

H

Hardened Steel

|

• | • |

|

M

Stainless Steel

|

• | • |

|

S

HRSA's

|

• | • |

|

K

Cast Iron

|

• | • |

|

N

Aluminium & Non-Ferrous

|

• | • |

Face Milling

Trochoidal Milling

Side Cutting

Slotting

Circular Interpolation

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

Or

Place your order without creating an account for extra convenience.