Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

Or

Checkout as a Guest

Place your order without creating an account for extra convenience.

MAIN STYLE TAGS

MOBILE VIEW HTML

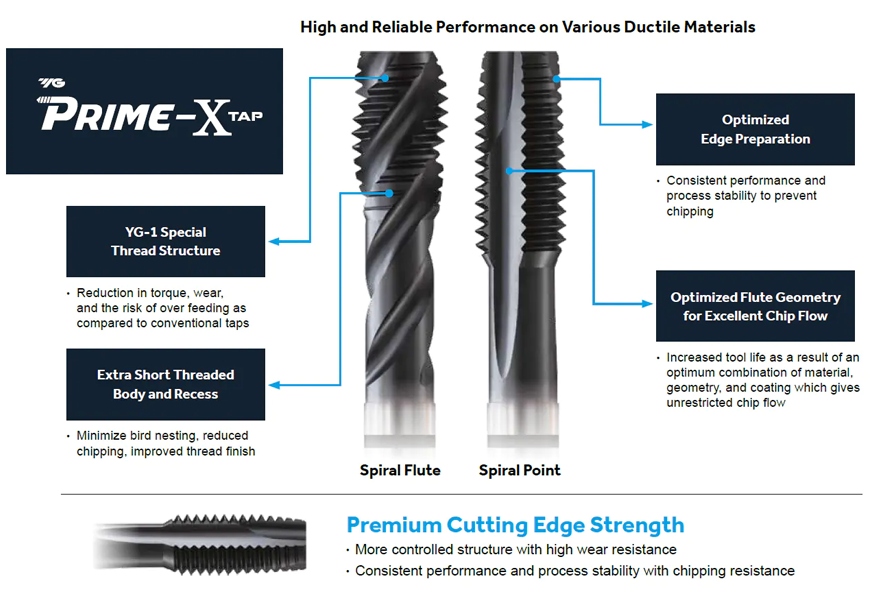

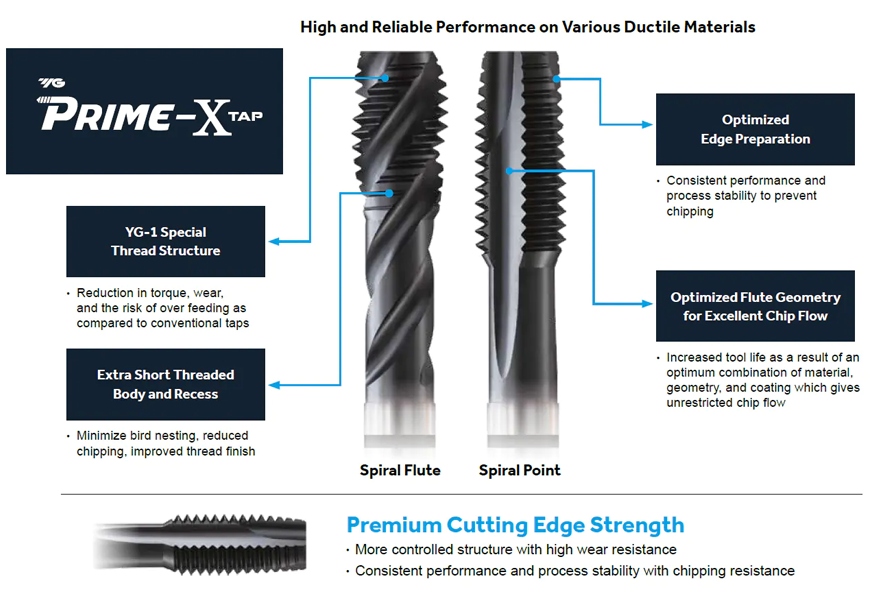

The number 1 choice for all-round high performance tapping on a wide range of materials.

Up to 50% higher cutting speeds compared to conventional HSSE taps

Up to 100% longer tool life compared to conventional HSSE taps

Extremely reliable with highly improved wear resistance

YG-1’s unique patented geometry prevents tap failure due to over feeding

Unique coating combined with premium powder metal substrate ensures excellent tool life

Prime-X taps are excellent on steel, stainless steel, cast iron & non-ferrous

The optimised flute geometry provides unrestricted chip flow

Minimises bird nesting, reduces chipping and improves thread finish

| Material | Excellent | Good |

|---|---|---|

|

P

Steel

|

• | • |

|

H

Hardened Steel

|

• | • |

|

M

Stainless Steel

|

• | • |

|

S

HRSA's

|

• | • |

|

K

Cast Iron

|

• | • |

|

N

Aluminium & Non-Ferrous

|

• | • |

Copy Milling

Face Milling

Shoulder Milling

Slotting

Trochoidal Milling

Circular Interpolation

| Low Carbon Steel HRc20 | Alloy Steel HRc32 | Hardened Steel HRc55 | Stainless Steel 316 | Grey Cast Iron | Inconel | |

|---|---|---|---|---|---|---|

| RPM | 2794 | 2540 | 762 | 1520 | 2030 | 444 |

| Feed (mm/min) | 8940 | 7111 | 1524 | 4256 | 4872 | 889 |

| Diameter | 25 | |||||

| Teeth | 4 | |||||

| Surface Speed (m/min) | 220 | 200 | 60 | 120 | 150 | 35 |

| Feed per Tooth | 0.8 | 0.7 | 0.5 | 0.7 | 0.6 | 0.5 |

| Depth of Cut (AP) | 0.7 | 0.7 | 0.5 | 0.7 | 0.7 | 0.5 |

| Depth of Cut (AE) | 25 | |||||

*Conservative example cutting data given. Tools can be run faster or slower depending on machine capability. Data based on ENMX06 insert.

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

Or

Place your order without creating an account for extra convenience.