MAIN STYLE TAGS

MOBILE VIEW HTML

i-X Mill

High precision dedicated milling system for copy & high feed milling

Exceptional performance, accuracy, tool life and surface finish across a wide range of materials with steel and carbide shank options

P

H

M

K

N

Browse the Range

Carbide i-X Mill

Straight Shank Holder

| Application |

|

| Diameters | 8-33mm |

Double core geometry for slotting and profiling, long tool life and best all-round performance

Steel i-X Mill

Straight Shank Holder

| Application |

|

| Diameters | 12-33mm |

Best for profiling offering high feed rates and tool stability

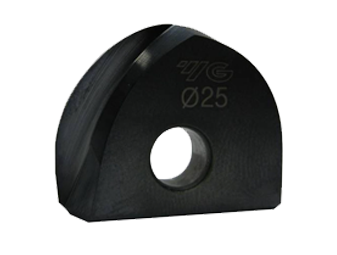

i-X Mill

Ball Nose Inserts

| Application |

|

| Diameters | 8-33mm |

Double core geometry for slotting and profiling, long tool life and best all-round performance

i-X Mill 5-Axis

Ball Nose Inserts

| Application |

|

| Diameters | 8-33mm |

Best for profiling offering high feed rates and tool stability

Advantages

Special Insert Grades

Each insert suitable for specific materials with special geometries

Replaceable Inserts

No need to replace the holder - just switch the insert. Great cost efficiency

High Precision

High accuracy strong clamping screw & high precision insert location

High Feed/Corner Radius

Holders for high feed & corner radius milling ensures highest accuracy & performance

Features

Ball Inserts

Special helical geometry prevents vibration and prolongs tool life

Polished Cutting Edges

Offers better wear resistance and improved surface roughness

Special Coating

Coatings offer high hardness and high thermal stability for faster speeds and feeds

Carbide Holders

For stable machining with reduced vibration and enhanced finish, longer tool life than steel holder

Insert Guide

| Insert Style | Series | Application | Description |

|---|---|---|---|

Ball Insert |

XMB110A | Steel <40 HRC |

Medium sharp cutting edge with Excellent chip control, ideal for softer and longer chipping steels |

| XMB120C | Pre-Hardened Steel 40-50HRC Cast Iron |

Stronger cutting edge, ideal for machining tool steels. Excellent tool life and surface finish | |

| XMB260T | Hardened Steel 50-65HRC |

Strongest cutting edge and ultrafine micrograin carbide substrate. Suitable for machining hardened steels | |

| XMB130A | Stainless Steel |

Specially designed cutting edge with web-thinning geometry, perfect for machining stainless steel without causing work hardening | |

| XMB110D | Graphite, Aluminium & Abrasive Non-Ferrous Metals |

DLC coating (diamond like carbon) has exceptional wear resistance in abrasive materials such as graphite, high silicon Aluminium and plastics. Long tool life and high-quality surface roughness can be achieved | |

Ball Insert Full Radius 220° |

XMM110V | 5 Axis Machining Steels <45HRC |

Full radius insert for complex 5 axis machining or creating undercuts in mould & die machining |

Corner Radius |

XMR260T | Hardened Steel 50-65HRC |

Special coating for longer-lasting cutting of high hardened steel. Wide range of radius available from 0.3 to 3.2mm |

| XMR120C | Pre Hardened Steels <50HRC Cast Iron |

Special geometry and coating ideal for use on carbon steels, alloy steels, tool steels, hardened steels. Wide range of radius available from 0.3 to 3.2mm | |

High Feed Corner Radius |

XMF110V | Steels <50HRC |

Feed rates over 7m/min can be achieved. When combined with dedicated high feed holders, better results are possible. Ideal for high-performance roughing and finishing |

Ball Insert Holders

| Holder | Geometry | Application | Benefits |

|---|---|---|---|

| Carbide | Straight Shank (With reduced neck) |

For use with ball nosed inserts Short to long reach applications |

Highest rigidity, especially in long reach applications, exceptional surface finish and improved tool life due to reduced vibration |

| Steel | Straight Shank (With reduced neck) |

For use with ball nosed inserts Short to medium reach applications with extra clearance |

Clearance on the neck diameter prevents interference when machining up to a shoulder |

| Straight Shank (with tapered neck) |

Higher rigidity than straight neck due to taper design, available in smaller diameters |

*Corner radius insert can be used with the ball holder. For a better precision in cutting, it is recommended to use the corner radius holder

Corner Radius / High Feed Holders

| Holder | Geometry | Application | Benefits |

|---|---|---|---|

| Steel | Straight Shank (With reduced neck) |

For use with corner radius/high feed inserts suitable for short to long reach applications | Clearance on the neck diameter prevents interference when machining up to a shoulder |

| Straight Shank (with tapered neck) |

For use with ball nosed inserts Short to medium reach applications with extra clearance |

Higher accuracy when using corner radius inserts higher rigidity than straight neck due to taper design, available in smaller diameters |

*Corner radius insert can be used with the ball holder. For a better precision in cutting, it is recommended to use the corner radius holder

Grade Guide

| Grade | Chipbreaker | Materials | Features & Benefits |

|---|---|---|---|

| PC2505 | MM | Hardened Steel 45-60HRC |

Ideal for continuous-light interrupted cutting at medium-low surface speeds on heat treated steel & high hardened steel with excellent wear resistance. |

| PC2501 | MM | Hardened Steel / Pre-Hardened Steel 35-50HRC |

Ideal for continuous-light interrupted cutting at medium-low surface speeds on high hardened steel & pre-hardened steel with excellent impact resistance. |

| PC3700 | MF MM |

Steel <40 HRC |

Dedicated steel grade for continuous-light interrupted cutting at medium-high surface speeds. Provides advanced performance & maximum efficiency. |

| PC5300 | MM MF ML |

Steel <40 HRC

Stainless Steel

HRSA's

Cast Iron

|

General PVD coated grade with high toughness for longer tool life. Suitable for light-heavy interrupted cutting at medium-high surface speeds. |

| PC5400 | MM MF ML |

Steel <35 HRC

Stainless Steel

HRSA's

Cast Iron

|

General purpose grade with excellent wear resistance & surface roughness when low speed machining. Ideal for continuous-heavy interrupted cutting. |

| PC6510 | MM | Cast Iron |

Specialised grade for multi-purpose milling applications of cast iron. Suitable for continuous-light interrupted cutting at medium-high surface speeds. |

| PC9530 | MM | Stainless Steel |

Ultra fine substrate for medium & roughing in stainless steel milling. Ideal for high feed continuous-light interrupted cutting. |

| H01 (Uncoated) | MA | Non-Ferrous |

Dedicated non ferrous grade for high speed, high feed milling & mirror surface finish. Uncoated polished grade for maximum swarf control in medium-high speed cutting. |

| UNC840 (CVD) | ML | HRSA's |

Premium grade for machining of HRSA including Inconel, Hastelloy, Titanium alloy etc. Ideal for continuous-light interrupted cutting at high speed-low feed machining. |

Application

Material Suitability

| Material | Excellent | Good |

|---|---|---|

|

P

Steel

|

• | • |

|

H

Hardened Steel

|

• | • |

|

M

Stainless Steel

|

• | • |

|

S

HRSA's

|

• | • |

|

K

Cast Iron

|

• | • |

|

N

Aluminium & Non-Ferrous

|

• | • |

Possible Machining Methods

Face Milling

Trochoidal Milling

Side Cutting

Slotting

Circular Interpolation

Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

Or

Checkout as a Guest

Place your order without creating an account for extra convenience.